VJ Instruments'

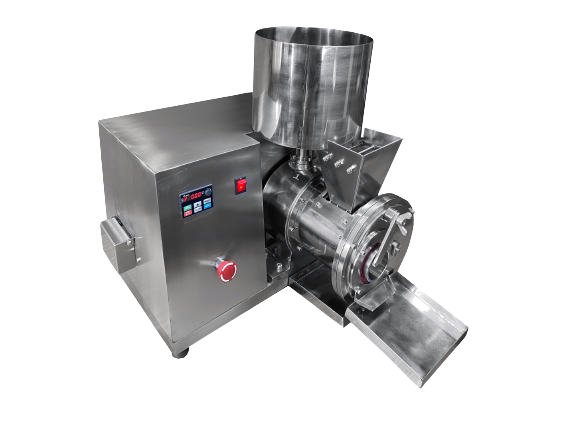

Lab-Scale Extruder & Spheronizer Combo

Lab-Scale Extruder and Spheronizer Combo is a seamlessly integrated system poised to redefine granulation in formulation research and product development. The Extruder component, featuring four interchangeable heads, facilitates versatile low-pressure granulation techniques on a bench-top scale, accommodating batches as small as 200 grams. Its adaptability and indicative results make it a cost-effective and efficient solution for evaluating diverse formulations.

Complementing the Extruder, the Spheronizer component offers precise control over spheronization processes, featuring a substantial 230 mm diameter friction plate capable of producing spheres ranging from 0.5 mm to 10.0 mm. With user-friendly features such as easy disassembly, GMP design, variable plate speeds, and a dedicated stainless steel control panel, this dynamic duo empowers researchers and product developers to seamlessly progress from extrusion to spheronization, unlocking new possibilities for innovation in pharmaceuticals, chemicals, and the food industry. The VJ Instruments Extruder and Spheronizer Combo stand as a cohesive and powerful platform, representing a significant leap forward in granulation technology.

Lab-Scale Extruder & Spheronizer Combo in Action

Application

Lab-Scale Extruder

A versatile Low pressure granulator tool from VJ Instruments. The VJ Instruments Multi Granulator is a bench- top device that allows formulation researchers and new product developers to readily evaluate the best of Four different types of low pressure granulation techniques— dome, cone, radial, and axial extrusion— and determine which one suits their product. The Multi Granulator’s size and unique design allow it to evaluate batches as low as 200 grams, saving time and money, yet generating product that is indicative of a full scale production system. Four types of extrusion—dome, Cone, axial, and radial—can be evaluated by simply changing the extrusion head. VJ Instruments offers four types of low pressure extruders.

Operation

The Multi Granulator is easy to setup and assemble with any of the four extrusion configurations for immediate use. A wet mixture is separately prepared manually or in a small mixer. The extruder is fitted with the appropriate die (or screen). The prepared wet material is manually fed through the feed hopper. The wet mass is transported to the extrusion area by a single feed screw. The wet material is gently wiped through the die (screen) yielding well formed extrudates.

Features

- Single screw extruder with variable speed (10-90 rpm) Easily converts into a dome, cone, radial, or axial extruder

- Capable of extruding granules from 0.3 mm to 8.0 mm diameter. Axial from 2.0 mm to 8.0 mm diameter; Radial from 0.6 mm to 1.2 mm diameter; Dome & Cone from 0.3 mm to 2.0 mm diameter

- GMP design with SS 316 contact parts

- Die is SS 316 ๏ 1.0hp 230VAC /3/60 variable speed drive for extrusion screw

- Sanitary clamps allow for quick disassembly, cleaning, and conversion to any of the three extrusion configurations. No tools required.

- Separate stainless steel control panel with motor starter

Application

Chemical / Agrochemical

✓ Herbicides / Insecticides / Fungicides

✓ Catalysts

✓ Flavors

✓ Neutraceuticals

Pharmaceuticals / Food

✓ Controlled Release Pellets

✓ Multi-Particulate Systems

✓ Sustained Release Polymer Coated Pellets

✓ Enteric Coated Pellets

Lab-Scale Spheronizer

The VJ Instruments Spheronizer is a bench top device that provides

researchers and new product developers a means to easily

evaluate the effectiveness of spheronization on their extruded

products. The size and unique features allow it to evaluate

batch sizes as small as one litre, while generating product

indicative of a full scale production system. The lab spheronizer

is designed to convert moist cylindrical extruded granules into

smooth, uniform spheres in a variety of applications.

Features

- Bench top device ideal for a laboratory environment

- Easy disassembly of process parts

- 230 mm diameter friction plate

- Capable of producing 0.5 mm to 10.0 mm spheres

- Friction plates available with groove spaces of 1-8 mm

- Friction plates available in various grid patterns

- Variable plate speeds between 600- 1800 rpm

- GMP design with SS 316 product contact parts 304SS jacketed bowl for heating/ cooling 1.0hp 230VAC /3 / 60 motor to drive friction plate

- Separate stainless steel control panel with motor starter and inverter

Operation

The Spheronizer can be easily assembled with the desired friction plate for spheronization. Moist granules, from

an extruder or mixer, are fed into the spinning friction plate and thrown against the inside of the Spheronization,

forming a “twisting rope”. Collisions of the particles with the wall, friction plate, and other particles result in plastic

deformation of the granules, forming spheres. The final shape of particles is time and formulation dependent.

Once the desired particle shape is achieved, the batch is discharged through a manual plug valve and discharge

chute, collected, and dried.

Technical Specification

Extruder Combo Machine Specifications

| Sr. No. | Specification | Details |

|---|---|---|

| 1 | Model No | VJEX – Combo |

| 2 | Certificates | GMP, ISO, CE |

| 3 | Type | Single Screw |

| 4 | Production Capacity | 2-6 kg/hr depends on formulation. |

| 5 | Perforated mesh hole diameter | Ø 1 mm standard. Optional with additional cost: Ø 0.5 mm Ø0.6 mm Ø 0.8 mm Ø 1.2 mm Ø 1.5 mm

|

| 6 | Product | Any Aqua base or solvent base formulation. |

| 7 | RPM of screw | 10 to 150 rpm |

| 8 | Hopper Discharge | Auto discharge by gravity |

| 9 | Electric Accessories | 230 V 1 Phase 50 Hz / 440 V 3 Phase 50 Hz |

| 10 | MOC Contact Parts | SS 316 |

| 11 | MOC Non-Contact Parts | SS 304 |

| 12 | Hardware | Standard Make (Bearing shaft seal of SKF etc or equivalent) |

| 13 | Finish | Non Contact Area Matt Finish Contact area Matt Finish Machine part- Machine Finish |

| 14 | HMI (Touch Screen) | Delta |

| 15 | Drive Motor | Crompton or equivalent |

| 16 | Reduction Gear Box | Standard Make. |

| 17 | Documents | User Manual, Warranty Certificate. |

| 18 | Electric Consumption | 1.0 Kw |

| 19 | Dimension (LXWXH) in mm | 425 mm (L) X 500 mm (W) X 575 mm (H) |

| 20 | Weight | 48 kg |

| 21 | Control Panel | 22 kg 300 mm (L) X 375 mm (W) X 475 mm (H) |

Spheronizer Combo Machine Specifications

| Sr. No. | Specification | Details |

|---|---|---|

| 1 | Model No | VJSP – Combo |

| 2 | Certificates | GMP, ISO, CE |

| 3 | Chequered Plater | 3.0 mm Pitch (Std) Optional with extra cost: 1.0 mm to 8.0 Pitch

|

| 4 | Production Capacity | 100 to 500 gm per batch (2-6 kg/hr depends on formulation.) |

| 5 | Product | Any Aqua base or solvent base formulation. |

| 6 | RPM | 100 to 1400 rpm |

| 7 | Electric Accessories | 230 V 1 Phase 50 Hz / 440 V 3 Phase 50 Hz |

| 8 | Air purged inlet | Through Fan |

| 9 | MOC Contact Parts | SS 316 |

| 10 | MOC Non-Contact Parts | SS 304 |

| 11 | Hardware | Standard Make (Bearing shaft seal of SKF etc or equivalent) |

| 12 | Finish | Non Contact Area Matt Finish Contact area Matt Finish Machine part- Machine Finish |

| 13 | Drive Motor | Crompton or equivalent |

| 14 | HMI (Touch Screen) | Delta |

| 15 | Documents | User Manual |

| 16 | Electric Consumption | 1 Kw |

| 17 | Dimension (LXWXH) in mm | 360 mm (L) X 425 mm (W) X 500 mm (H) |

| 18 | Weight | 48 Kg |

Note: Capacities mentioned above depend on samples used and may vary accordingly. VJ Instruments product development is a continuous process so specifications may change without prior notification.

Safety Features

- Emergency stop switch

- Auto stop feature when process time completes

Certifications

01.

CE Certificate

02.

GMP Certificate

03.

ISO Certificate

04.

MSME Certificate

Frequently Asked Questions

We understand that you may have questions about our Lab-Scale Extruder Spheronizer Combo, its applications, and how it can benefit your specific needs. Here are some common questions and answers to provide you with quick and helpful information:

What is an extruder machine and how does it work?

What industries use pellets making machines?

Pellets making machines are widely used in pharmaceuticals for controlled drug delivery, in the chemical industry for catalyst formation, and in agriculture for producing feed or fertilizer pellets. Manufacturers like VJ Instruments offer specialized machines tailored to meet different industry standards and production needs.

What are the benefits of using extruders machines in pharmaceutical production?

Where can I find reliable extruder machine manufacturers in India?

How does a mini lab extruder differ from industrial extruder machines?

What is an extruder and how is it used in manufacturing?

What are the advantages of using a screw extruder machine?

What should I consider when choosing single screw extruder manufacturers?

What factors influence the price of a pellet machine in India?

What key features should I look for in an extruder for lab?

What is the primary function of the Lab-Scale Extruder & Spheronizer Combo?

What batch sizes can be accommodated by the lab-scale extruder?

Can the extruder handle different low-pressure granulation techniques?

What is the diameter range for the spheres produced by the spheronizer?

Are there specific applications for the Lab-Scale Extruder & Spheronizer Combo in the pharmaceutical industry?

How user-friendly is the combo for researchers and product developers?

Can the Lab-Scale Extruder & Spheronizer Combo be utilized in the food industry?

International Clients

Industrial Clients

IITs, AIIMS, CSIR, Government and Private Institutes

Related Products

Lab-Mini Screw Extruder

VJ Instruments’ Lab-Mini Screw Extruder: Tailored Solutions for Pharmaceutical Pelletization Screw Extruders are versatile and

Lab-Mini Spheronizer

VJ Instruments’ Lab-Mini Spheronizer: Solutions for Pharmaceutical Spheronization Welcome to the world of pharmaceuticals and

Hot Melt Extruder

VJ Instruments’ Hot Melt Extruder: Revolutionizing Pharmaceutical Formulations Welcome to VJ Instruments, your trusted source

Die Roller Extruder

VJ Instruments’ Die Roller Extruder: Precision Extrusion Made Easy The Die Roller Extruder is a