VJ Instruments'

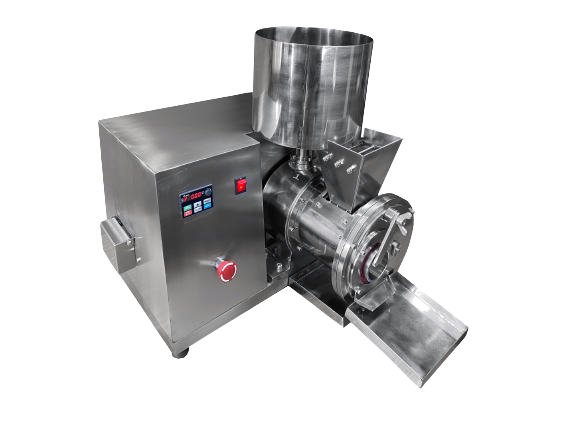

Lab-Mini Screw Extruder: Tailored Solutions for Pharmaceutical Pelletization

Lab-Mini Screw Extruder in Action

Application

Size Variability

Screw Extruders are widely employed for creating pharmaceutical pellets with diverse size requirements. Whether you need fine particles as small as 400 microns or larger pellets up to 2000 microns, these machines can handle the task with precision.

Gentle Compaction

One of the key advantages of using a Screw Extruder is its ability to provide mild compaction. This characteristic is particularly valuable for pharmaceutical formulations, ensuring the integrity of sensitive materials.

Components

- Hopper: The extruder features a hopper for loading wet mass, facilitating the efficient input of materials.

- Internal Blades: These blades are connected to gears, which rotate and push the material systematically into the feed hopper of the Extruder Chamber.

- Extrusion Chamber: The chamber is jacketed from the outside, allowing for the circulation of cold water. This feature helps maintain the temperature of the product, which is vital when working with sensitive materials.

- Single Screw: The extrusion chamber contains a single screw responsible for transferring the material towards the pressing cam and out through the perforation of the desired diameter screen.

Versatile Output

Screw Extruders are available for R&D batches, with a minimum output of 250 grams. This flexibility is ideal for research and development purposes.

Compliance and Ease of Use

Our Screw Extruders are cGMP-compliant equipment. They are designed as self-standing Table Top Models for R&D scale operations, equipped with a built-in electrical panel for ease of maintenance.

Advantages

Pharmaceutical Benefits

The use of pellets as a dosage form offers distinct advantages within the pharmaceutical industry, including:

- Flexibility: Capable of solution/suspension layering and powder layering.

- Minimal Dust: The process minimizes dust in the working environment, enhancing safety and cleanliness.

- Improved Flow: Pellets exhibit improved flow characteristics.

- Enhanced Solubility and Dispersibility: Pharmaceutical pellets often demonstrate better solubility and dispersibility.

- Improved Cosmetics: Aesthetically, pellets can enhance the final product’s appearance.

Technical Specification

| Sr. No. | Specification | Details |

|---|---|---|

| 1 | Model No | VJEX – 01 |

| 2 | Certificates | GMP, ISO, CE |

| 3 | Type | Single Screw |

| 4 | Production Capacity | 2-6 kg/hr depends on formulation. |

| 5 | Perforated mesh hole diameter | Ø 1 mm standard.

Optional with additional cost:

Ø 0.5 mm

Ø 0.6 mm, Ø

0.8 mm

Ø 1.2 mm

Ø 1.5 mm

|

| 6 | Product | Any Aqua base or solvent base formulation. |

| 7 | RPM of screw | 10 to 150 rpm |

| 8 | Hopper Discharge | Auto discharge by gravity |

| 9 | Electric Accessories | 230 V 1 Phase 50 Hz |

| 10 | MOC Contact Parts | SS 316 |

| 11 | MOC Non-Contact Parts | SS 304 |

| 12 | Hardware | Standard Make (Bearing shaft seal of SKF etc or equivalent) |

| 13 | Finish | Non Contact Area Matt Finish Contact area Matt Finish Machine part- Machine Finish |

| 14 | VFD | Delta |

| 15 | Drive Motor | Crompton or equivalent |

| 16 | Reduction Gear Box | Standard Make. |

| 17 | Documents | User Manual, Warranty Certificate. |

| 18 | Electric Consumption | 1 kWh |

| 19 | Dimension (LXWXH) in mm | 525 mm (L) X 305 mm (W) X 455 mm (H) |

| 20 | Weight | 50 kg. (Approximately) |

Safety Features

- Emergency stop switch.

- Auto stop feature when process time completes.

Certifications

01.

CE Certificate

02.

GMP Certificate

03.

ISO Certificate

04.

MSME Certificate

Frequently Asked Questions

We understand that you may have questions about our Lab-Mini Screw Extruder, its applications, and how it can benefit your specific needs. Here are some common questions and answers to provide you with quick and helpful information:

What is a Lab-Mini Screw Extruder, and how does it work?

What sizes of pellets can the Lab-Mini Screw Extruder produce?

Why is gentle compaction important in pharmaceutical pelletization?

What are the key advantages of using pellets as a dosage form in pharmaceuticals?

Is the Lab-Mini Screw Extruder compliant with industry standards and certifications?

Can the Lab-Mini Screw Extruder be used for research and development purposes?

What safety features does the Lab-Mini Screw Extruder include?

How can I learn more about the Lab-Mini Screw Extruder and its capabilities for small-scale trials?

International Clients

Industrial Clients

IITs, AIIMS, CSIR, Government and Private Institutes

Related Products

Lab-Scale Screw Extruder & Spheronizer Combo

VJ Instruments’ Lab-Scale Extruder & Spheronizer Combo Lab-Scale Extruder and Spheronizer Combo is a seamlessly

Lab-Mini Spheronizer

VJ Instruments’ Lab-Mini Spheronizer: Solutions for Pharmaceutical Spheronization Welcome to the world of pharmaceuticals and

Hot Melt Extruder

VJ Instruments’ Hot Melt Extruder: Revolutionizing Pharmaceutical Formulations Welcome to VJ Instruments, your trusted source

Die Roller Extruder

VJ Instruments’ Die Roller Extruder: Precision Extrusion Made Easy The Die Roller Extruder is a