VJ Instruments'

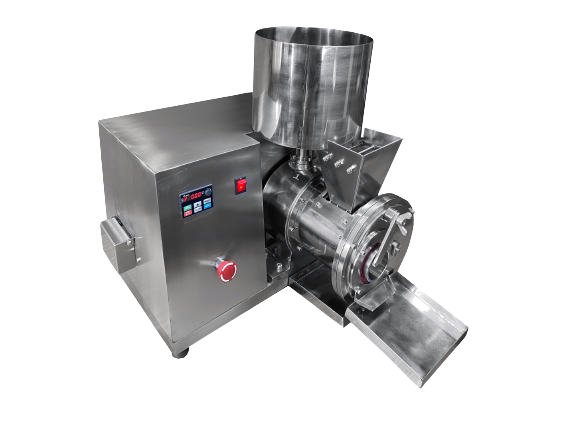

Hot Melt Extruder: Revolutionizing Pharmaceutical Formulations

Application

Hot Melt Extruders represent an evolution of screw extruders, where a meticulously controlled heater warms the barrel, transferring the heat to the product. This process results in the extrusion of a molten polymeric mass through die plates. The extruder’s design allows for gentle compaction, making it an ideal choice for numerous pharmaceutical formulations, particularly those sensitive in nature.

Purpose

The primary purpose of the Hot Melt Extruder is to facilitate the production of pharmaceutical formulations with precision and efficiency. The equipment’s design ensures that the product’s temperature is maintained, and the material is processed consistently, meeting the stringent requirements of the pharmaceutical industry.

Features and Applications

Our Hot Melt Extruder, the VJHME-Labmini, boasts several key features and applications:

- Stainless Steel Construction: Model No. VJHME-Labmini is constructed with stainless steel 316 for contact parts, ensuring durability and hygiene. The rest of the equipment is made from stainless steel 304.

- Pellet Processing Efficiency: This extruder ensures the highest level of product performance and efficient processing, making it suitable for a wide range of pharmaceutical formulations.

- Variable Die Plate Diameters: It comes with a standard 1.0 mm slit diameter die plate, but different diameters are available upon request, allowing customization to suit your specific needs.

- Compact and User-Friendly: The equipment is available for R&D batches with a minimum output of 250 gms. Its compact, self-standing table-top model is perfect for R&D scale operations. It features a built-in electrical panel for easy maintenance, ensuring smooth operation.

Technical Specification

Here are the technical specifications for our Hot Melt Extruder, Model No. VJHME-Labmini:

| Specification | Details |

|---|---|

| Construction | Stainless steel 316 for contact parts, stainless steel 304 for the rest |

| Slit Diameter (Standard) | 1.0 mm |

| Capacities | Depend on samples used and may vary accordingly |

| Change Notification | Specifications may change without prior notification |

*Capacities mentioned above depend on samples used and may vary accordingly.

Note: VJ Instruments product development is a continuous process so specifications may change without prior notification.

Safety Features

- Emergency stop switch.

- Auto stop feature when process time completes.

Certifications

01.

CE Certificate

02.

GMP Certificate

03.

ISO Certificate

04.

MSME Certificate

Frequently Asked Questions

We understand that you may have questions about our Hot Melt Extruders, its applications, and how it can benefit your specific needs. Here are some common questions and answers to provide you with quick and helpful information:

What is a Hot Melt Extruder, and how does it work?

What are the primary applications of the Hot Melt Extruder?

What are the key features of the VJHME-Labmini Hot Melt Extruder?

What is the capacity of the VJHME-Labmini Hot Melt Extruder?

Is the VJHME-Labmini compliant with cGMP (current Good Manufacturing Practices) standards?

Yes, the VJHME-Labmini is a cGMP-compliant piece of equipment. It meets the high standards required in pharmaceutical manufacturing.

Can I get customized die plate diameters for the extruder?

International Clients

Industrial Clients

IITs, AIIMS, CSIR, Government and Private Institutes

Related Products

Lab-Scale Screw Extruder & Spheronizer Combo

VJ Instruments’ Lab-Scale Extruder & Spheronizer Combo Lab-Scale Extruder and Spheronizer Combo is a seamlessly

Lab-Mini Screw Extruder

VJ Instruments’ Lab-Mini Screw Extruder: Tailored Solutions for Pharmaceutical Pelletization Screw Extruders are versatile and

Lab-Mini Spheronizer

VJ Instruments’ Lab-Mini Spheronizer: Solutions for Pharmaceutical Spheronization Welcome to the world of pharmaceuticals and

Die Roller Extruder

VJ Instruments’ Die Roller Extruder: Precision Extrusion Made Easy The Die Roller Extruder is a