VJ Instruments'

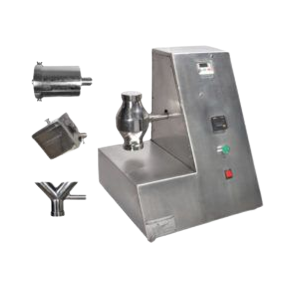

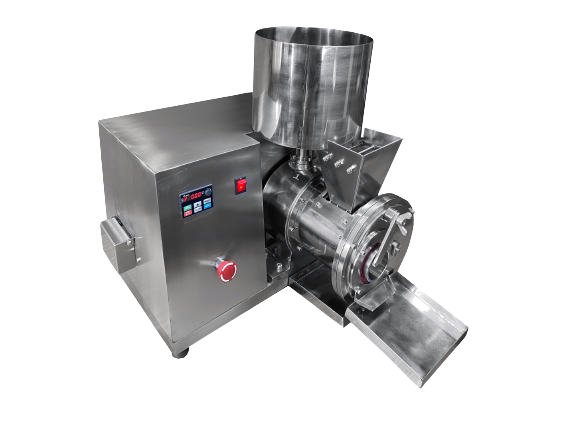

Blend It Right: The Ultimate All-Purpose Mixing Machine

Unveiling the Magic: How the All-Purpose Mixing Machine Works

Different types of blending machines offered by VJ Instruments.

Double Cone Blender

The Double Cone Blender is a vital piece of equipment used in various industries, including healthcare, food, chemical, cosmetics, detergents, fertilizers, and plastics, for the purpose of creating homogeneous solid-solid mixtures. This versatile blender offers an efficient and effective solution for blending powders, such as pharmaceutical recipients, chemicals, and food products, ensuring uniform mixing and easy discharge. The primary purpose of the Double Cone Blender is to facilitate the blending of powders in the production of pharmaceutical solid dosage forms. It enables the homogeneous mixing of active pharmaceutical ingredients (API) with various excipients, including fillers, binders, lubricants, and disintegrates, to ensure a consistent mixture for manufacturing processes.

V-Cone Blender

The V-Cone Blender is a critical tool in the production of homogeneous solid-solid mixtures. It plays a crucial role in various industries, including healthcare, food, chemical, cosmetics, detergents, fertilizers, and plastics, ensuring precise blending and short mixing cycles. The primary purpose of the V-Cone Blender is to create homogeneous mixtures by blending dry powders and granulated products. It’s ideal for products with uniform size and density, and it excels in sanitary applications requiring fast and thorough cleaning.

Cube Mixer

The Cube Mixer is an essential tool for producing homogeneous solid-solid mixtures, widely used in industries such as healthcare, food, chemical, cosmetics, detergents, fertilizers, and plastics. The Cube Mixer utilizes three stainless steel mixing rods to create a tumbling effect, resulting in a homogeneous mixture in the shortest possible time. It’s an important component in the production of pharmaceutical solid dosage forms, ensuring the uniform blending of active pharmaceutical ingredients (API) with various excipients.

Ball Mill Machine

The Ball Mill Machine is a versatile tool used for grinding crystalline materials and mixing both dry and wet materials, making it a valuable asset in various industries. The primary purpose of the Ball Mill Machine is to facilitate the grinding and mixing of crystalline materials, enabling them to be used in various industrial processes.

Application

Applications:

The blending process is essential in many manufacturing workflows, especially when new excipients need to be added to a mixture. The All-Purpose Machine can be used in numerous industries, including pharmaceuticals, chemicals, and food production, to create homogenous mixtures of powders. Its key features include:

- Efficiency: The machine ensures efficient mixing of pharmaceutical recipients, chemicals, and food products, resulting in a homogeneous blend.

- Optimum Volume: With an effective volume that optimizes homogeneity (ranging between 35-70% of the gross volume), this machine is a reliable choice for blending.

- Conical Shape: The conical shape, along with elongated planes at both ends, facilitates uniform mixing and easy discharge, ensuring consistency in your mixtures.

Pharmaceutical Solid Dosage Forms:

In the pharmaceutical industry, blending powders is a critical step in the production of solid dosage forms. Active Pharmaceutical Ingredients (API) are typically in powder form and need to be blended with other powders (excipients) to create tablets. The blending efficiency depends on factors such as the degree of homogeneity and blending time, which are influenced by material properties and blender geometry.

Ingredients for Blending:

Blending typically involves an Active Pharmaceutical Ingredient (API) and various excipients, including fillers, binders, lubricants, and disintegrates. This process ensures a homogeneous mixture of all ingredients in each manufacturing step.

Technical Specification

| Technical Specifications | Details |

|---|---|

| Model No. | VJAP-01 |

| Main Drive | Maintenance-free horizontal drive featuring a 40-watt induction motor. |

| Drive Power | 0.2 kW/0.25hp, Single phase (1PH), 230V. |

| Gearbox Ratio | 1:10, capable of speeds up to 150 rpm. |

| Speed Control | Adjustable from 5 to 150 rpm with a precise automatic timer (0 to 999 min). |

| Installation | Easy attachment on a single screw. Power consumption: 230V, 50Hz. |

| Capacity | Available in 1 lit. (Standard), with optional sizes of 500 ml (0.50 lit) and 750 ml (0.75 lit). |

| Main Drive Dimensions | Overall Dimensions: 410mm X 512mm |

| Weight | Approximately 18KG |

| Construction | GMP construction with polished S. S. sheets, featuring S.S. 316 contact parts and 304 non-contact parts. |

Safety Features

- Emergency stop switch

- Auto stop feature when process time completes

Certifications

01.

CE Certificate

02.

GMP Certificate

03.

ISO Certificate

04.

MSME Certificate

Frequently Asked Questions

We understand that you may have questions about our All-Purpose Mixing Machine, its applications, and how it can benefit your specific needs. Here are some common questions and answers to provide you with quick and helpful information:

What is the All-Purpose Mixing Machine used for?

How does the machine ensure uniform blending?

Can I control the speed of the mixing process?

What is the capacity of the All-Purpose Mixing Machine?

Is it easy to install and operate the machine?

What materials is the machine constructed from?

What are the critical factors influencing blending efficiency?

International Clients

Industrial Clients

IITs, AIIMS, CSIR, Government and Private Institutes

Related Products

Lab-Scale Rapid Mixer Granulator

VJ Instruments’ Lab-Scale Rapid Mixer Granulator: Perfect for Small-Scale Granulation Trials Welcome to VJ Instruments,

Lab-Scale Fluid Bed Dryer

VJ Instruments’ Lab-Scale Fluid Bed Dryer: Precision Drying for Research and Development Welcome to our

Lab-Scale Screw Extruder & Spheronizer Combo

VJ Instruments’ Lab-Scale Extruder & Spheronizer Combo Lab-Scale Extruder and Spheronizer Combo is a seamlessly

Lab-Mini Screw Extruder

VJ Instruments’ Lab-Mini Screw Extruder: Tailored Solutions for Pharmaceutical Pelletization Screw Extruders are versatile and

Lab-Mini Spheronizer

VJ Instruments’ Lab-Mini Spheronizer: Solutions for Pharmaceutical Spheronization Welcome to the world of pharmaceuticals and

Fluidized Bed Processor

VJ Instruments’ Fluidized Bed Processor: Revolutionizing Research and Development Welcome to the world of innovation

Fluid Bed Top Coater

VJ Instruments’ Revolutionizing Coating and Drying: Introducing the Fluid Bed Top Coater VJ Instruments proudly

R&D Tablet Coater

VJ Instruments’ Efficient Small-Batch Tablet Coating Solution for Pharmaceutical R&D The Pharma R&D Tablet Coater

Hot Melt Extruder

VJ Instruments’ Hot Melt Extruder: Revolutionizing Pharmaceutical Formulations Welcome to VJ Instruments, your trusted source

Die Roller Extruder

VJ Instruments’ Die Roller Extruder: Precision Extrusion Made Easy The Die Roller Extruder is a