VJ Instruments'

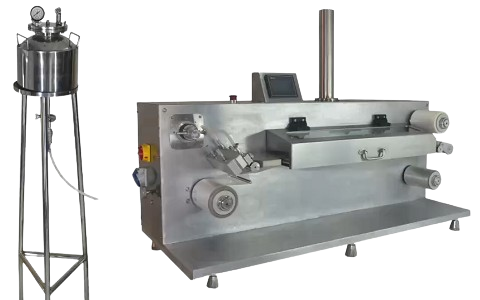

Cutting-Edge Tabletop Transdermal Patch Machine: Revolutionizing TDP and ODF Production

Precision Film Production with VJ Instruments Table-Top Coating Machine

Application

To make oral dissolvable film and transdermal patches conventionally glass petriplates , Teflon coated petriplates and Teflon petriplates are commonly used. The major disadvantage of petriplate is time consuming process that takes hours and reproducibility of the same thickness is less.

SOLUTION

VJ instrument rectified this error by developing self- drying tabletop semiautomatic machine with uniform film making dragger machine. This machine can be used for long single film with uniform thickness.

FEATURES

The film former machine has the elegant exterior fabricated of Stainless Steel box with toughened glass table- top. We can maintain the temperature of the glass tabletop from ambient to 100 C with the help of digital thermostat. The unique dragger is provided with digital screw gauges to make uniform thick films.

Operation

The Film Former is a versatile semi-automatic unit equipped with essential components, including a dragger with digital screw gauges, a stainless steel body, a heater, a glass tabletop, and a digital temperature controller. It serves as a key tool for producing oral dissolving films and transdermal films with precision.

In the first step, set the temperature of the glass tabletop according to the specific solution or suspension being used. This can be easily adjusted via the control panel.

Next, fine-tune the dragger screw gauges to achieve the desired height, considering the impact of evaporation on the film’s thickness.

Position the dragger and dragger guide on the glass tabletop in preparation for the film-making process.

Prepare a bubble-free solution or suspension containing the necessary components, including the drug, film former, and plasticizer.

For oral film production, use the dragger to apply the solution evenly onto the glass tabletop.

If producing transdermal patches (TDP), start by placing a release liner on the glass tabletop. Then, cast the film onto it and apply the backing membrane.

Once the films are dry, carefully remove them from the glass tabletop. They can then be cut according to the required content and weight specifications, ensuring uniformity.

This step-by-step process, facilitated by the Film Former, simplifies film production, making it efficient and precise for oral dissolving films and transdermal patches.

Technical Specification

| Sr. No. | Specification | Details |

|---|---|---|

| 1 | Model No | VJODF-Lab |

| 2 | Certificates | GMP, ISO, CE |

| 3 | Production Capacity | 1 inch X 1 inch – 150 ODF in an hour. |

| 4 | Size of Film drawn | 75 mm width X 500 mm Length. |

| 5 | Coating Accuracy | +/- 1 to 5 μm for a 100 μm dry coating over the entire coating width |

| 6 | MOC Non-Contact Parts | SS 304 |

| 7 | MOC Contact Parts | Toughened Glass & Aluminium |

| 8 | Product | Any Aqua base or solvent base formulation. |

| 9 | Heater | Heater of 1 kW is provided in the insulating box to achieve the temperature from ambient to 100 C of glass table top. |

| 10 | Control Panel | Advance control panel with a digital temperature controller helps to control the temperature of the tabletop with accuracy of +/- 1degree Celsius. |

| 11 | Electric Accessories | 230 V 1 Phase 50 Hz |

| 16 | Documents | User Manual, Warranty Certificate. |

| 17 | Electric Consumption | 1 Kw |

| 18 | Dimension (LXWXH) in mm | 657 mm (L) X 581 mm (W) X 183 mm (H) |

| 19 | Weight | 22 kg. (Approximate) 75 kg. with packing (Approximate) |

Safety Features

- Emergency stop switch.

- Auto stop feature when process time completes.

Certifications

01.

CE Certificate

02.

GMP Certificate

03.

ISO Certificate

04.

MSME Certificate

Frequently Asked Questions

These FAQs provide essential information about the VJ Instruments table-top Film Former coating machine, its capabilities, and its benefits for potential users and customers.

What is the primary purpose of the VJ Instruments table-top Film Former coating machine?

What sets this machine apart in terms of product quality and accuracy?

How does the machine achieve uniform film thickness?

What are the dimensions of films that can be produced using this machine?

Is the machine compatible with different types of solvents?

How is the temperature of the glass tabletop controlled?

What type of control panel is available for this machine?

The machine is equipped with an advanced control panel featuring a digital temperature controller, ensuring accurate and user-friendly operation.

Does the machine require additional drying after film production?

International Clients

Industrial Clients

IITs, AIIMS, CSIR, Government and Private Institutes

Related Products

Advanced TDP & ODF Machine Pilot Scale

VJ Instruments’ Advanced TDP & ODF Machine Pilot Scale The VJ Instruments Advanced TDP &