VJ Instruments'

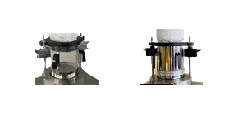

Lab-Scale Fluid Bed Dryer: Precision Drying for Research and Development

Efficient Drying with our Single Chamber Fluidized Bed Dryer

Enhancing Drying Efficiency with our Three Chamber Fluid Bed Dryer

Application

The air stream of the fluid bed dryer extracts moisture from the particles and then exits through the filter bag in the cover. Using the quick-clamp cover with the filter fleece insert is advisable when dealing with products finer upto 100 μm in diameter. The 1000 watt blower provides an air volume of 185 m3/h at idle speed; heater output is 2000 watts. The air volume, heating power and temperature are infinitely adjustable. Temperature control is effected using he display gauge.

Operation

The following steps are involved in the fluidization process by VJ Instruments’ fluid bed dryer.

- Material to be dried is placed in bowl type vessel.

- The air is introduced from the bottom and heated at the required temperature by heaters.

- The air is filtered through the filters and then passes through the material bed.

- The air flow is generated by fans fitted in the equipment.

- The airflow rate and the operating temperature are adjusted by the control panel.

- As the flow of air increases the bed expands and the particles of the powders starts to rise up in a turbulent motion.

- Regular contact with air causes the material to dry.

- The leaving the FBD passes through the filters to collect the fine particles of the material.

- FBD bags have finger link shape to increase the volume of the drying bed that helps to increase the drying rate and decrease the drying time.

- The vaporized liquid is carried away by the drying gases.

Technical Specification

| Sr. No. | Specification | Details |

|---|---|---|

| 1 | Model No | VJFBD-Lab |

| 2 | Certificate | GMP, ISO, CE |

| 3 | Material of Contraction (MOC) | Contact Part SS 316 & Glass Non-Contact Part SS304/Aluminum |

| 4 | Application | Drying |

| 5 | Feed Material | Agriculture, biology, chemistry/plastics, construction materials, environment/recycling, food, medicine/pharmaceuticals |

| 6 | Feed material Size | Bulk materials and solid |

| 7 | Material feed size | > 100 μm (depending on feed material and instrument configuration/settings) |

| 8 | Air Volume flow | Through blower. |

| 9 | Operation | Through HMI |

| 10 | Time Setting | Through HMI – Digital 1-99 min / Continuous |

| 11 | Storable SOPs | 99 |

| 12 | Temperature control | Continuously adjustable, 40°C-100°C (depending on air throughput rate) Dry Run Temp: 32°C Blower speed min – 58°C Blower speed maximum in standard room temp 27°C. |

| 13 | Container Volume | • 6 Litre

|

| 14 | Electric Points Required | Main machine – 16 Amp. |

| 15 | Electrical Supply | Single Phase 220V 50Hz |

| 16 | Power connection | Single Phase |

| 17 | Dimension (LXWXH) in mm | 600 mm X 480 mm X 621 mm approximately 762 mm X 685 mm X 762 mm With packing (approximately) |

| 18 | Weight | 38 kg approximately 70-90 kg with packing depending on accessories. |

Note: Capacities mentioned above depend on samples used and may vary accordingly. VJ Instruments product development is a continuous process so specifications may change without prior notification./em>VJ

Safety Features

- Emergency stop switch.

- Auto stop feature when process time completes.

Certifications

01.

CE Certificate

02.

GMP Certificate

03.

ISO Certificate

04.

MSME Certificate

Frequently Asked Questions

We understand that you may have questions about our Lab-Scale Fluid Bed Dryer, its applications, and how it can benefit your specific needs. Here are some common questions and answers to provide you with quick and helpful information:

A Lab-Scale Fluid Bed Dryer is a versatile piece of equipment used for small-scale drying experiments and product development. It allows researchers and engineers to mimic industrial drying conditions on a smaller scale, enabling precise control and optimization of the drying process.

Our Lab-Scale Pilot Fluid Bed Dryer can handle a wide range of materials, including pharmaceutical powders, food products, chemical compounds, granules, and more. It is suitable for drying coarse, fine, crystalline, fibrous, or leafy materials.

The dryer uses fluid bed drying principles, suspending and agitating particles in a stream of hot air or gas. This maximizes heat and mass transfer, reducing drying times and energy consumption, while maintaining product quality.

Yes, the dryer is equipped with advanced control systems that allow precise regulation of temperature, airflow rate, and drying time. This level of control enables you to tailor the drying process to your specific requirements.

Safety is a top priority. Our dryer is designed to prevent dust explosions and other hazards commonly associated with drying processes. It meets strict safety standards to ensure the well-being of your team and facility.

The dryer is ideal for applications such as pharmaceutical research and development, chemical process optimization, food product development, material testing and characterization, and innovation in drying techniques. It supports a wide range of industries and research fields.

Yes, the insights gained from lab-scale experiments are invaluable for scaling up to industrial dryers. Our experts can assist you in the transition to large-scale production, ensuring a seamless and efficient process.

Our drying guides are available for download on our website. You can access a wealth of knowledge on best practices, case studies, and the latest advancements in drying technology. Visit the Drying Guides section for more information.

If you have any questions or require technical assistance related to our Lab-Scale Pilot Fluid Bed Dryer or drying processes, our dedicated technical support team is ready to help. You can reach out to us by visiting the Contact Technical Support section.

To discover more about our company, our commitment to innovation, and our dedication to providing cutting-edge equipment for research and development, visit the About Us section on our website.

International Clients

Industrial Clients

IITs, AIIMS, CSIR, Government and Private Institutes

Related Products

Lab-Scale Rapid Mixer Granulator

VJ Instruments’ Lab-Scale Rapid Mixer Granulator: Perfect for Small-Scale Granulation Trials Welcome to VJ Instruments,

Fluidized Bed Processor

VJ Instruments’ Fluidized Bed Processor: Revolutionizing Research and Development Welcome to the world of innovation

Fluid Bed Top Coater

VJ Instruments’ Revolutionizing Coating and Drying: Introducing the Fluid Bed Top Coater VJ Instruments proudly

R&D Tablet Coater

VJ Instruments’ Efficient Small-Batch Tablet Coating Solution for Pharmaceutical R&D The Pharma R&D Tablet Coater