VJ Instruments'

Efficient Small-Batch Tablet Coating Solution for Pharmaceutical R&D

Explore our revolutionary solution for pharmaceutical research and development – the R&D tablet coating machine.

Application

Coating small batches of the tablets and granules.

REQUIREMENT

Research and development department of pharmaceutical companies had to manufacture unnecessary quantities of test drugs due to existing standards coating facilities which is resulted in huge wastage of effort as well as money.

SOLUTION

The new R & D tablet coating machine is designed to fulfill the specific need, with the help of unique array of smaller coating pan sizes of 4” & 6” which ensures the quantity of the test batch never exceeds the requirement.

FEATURES

The R & D tablet coating machine has the exterior appearance of an elegant fabricated box with coating pan supported in a tangential position of 35° to 45°. The entire drive mechanism is concealed with the box leaving only the hub, supporting the coating pan, projected outwards to enable vertical rotary momentum.

COATING PAN

Coating pan has been made from pure SS 304/SS 316 quality material, it consists of central cylindrical portion. Opening front side known as “pan mouth”. Baffles are

provided along the interior walls for efficient coating. The pan is detachable and available in an array of sizes 4” and 6”. Pan rpm can be set from 3 to 100 rpm

HEATER

The heater heats the inlet air at the desired temperature required to dry the tablets. It can be controlled to deliver the air at 30 C (ambient) to 80 C.

EXHAUST PIPE

Unwanted fumes and dust (generated by core tablets & coating material) can be cleared through the exhaust pipes from the coating pan.

AIR FILTER & CONTROLLER

It filters and removes moisture coming from compressor and also controls the flow rate. We can set air pressure in psi or bar.

CONTROL PANEL

Advanced control panel offers complete control over the various setting for the coater.

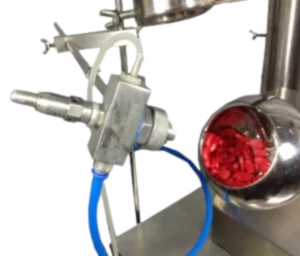

SPRAY GUN

Spray gun delivers droplets of the coating solution onto the tablet bed. Its superb performance is achieved by the use of a new range of nozzles made by pure SS 304/SS 316 & metered

PERISTALTIC PUMP

Peristaltic pump delivers exact amount of coating solution to the spray gun through silicon pipe dozing with the help of a peristaltic pump. It is easily adjustable along with its stand.

Operation

The R&D Coater is a versatile and semi-automatic unit designed for pharmaceutical research and development. This integrated system comprises a stainless steel coating pan, a precision spraying system, a hot air blower, and an efficient exhaust system. It harnesses the rotary motion of the coating pan to gently tumble the tablets or granules contained within it. Inside the pan, strategically placed baffles tilt the contents to ensure uniform and efficient coating.

For film coating, a specialized spray gun is employed to disperse finely nebulized droplets of the coating solution onto the moving bed, ensuring consistent coverage across all tablets. To complete the process, a stream of hot air is directed onto the tablet bed, with the exhaust temperature ranging between 60°C and 80°C, enhancing overall performance.

The advanced control panel offers precise control over various settings, including temperature and rotation speeds, allowing for tailored adjustments to meet specific research needs. When introducing tablets or granules into the pan or retrieving them, a scoop should be used. The optimal parameters for coating should be determined through experimentation and trials, ensuring the highest quality results in pharmaceutical research and development.

Technical Specification

| Sr. No. | Specification | Details |

|---|---|---|

| 1 | Model No | VJRDC – 01 |

| 2 | Certificate | GMP, ISO, CE |

| 3 | Pan Size & MOC | Pan 4” & 6” with Baffles Standard SS316 Optional 8” & 12” available (On demand with extra Cost) |

| 4 | Capacity In Kg | Depending on density of material capacity vary. 4” – 30 to 100 gm / 6” – 150-250 gm 8” – 300 – 800 gm / 12” – 1kg to 2 kg |

| 5 | Pan Speed RPM | 5 to 100 RPM |

| 6 | Main Drive HP | 0.05HP (0.037Kw) |

| 7 | Blower For Hot Air Watt/CFM | 71 watt/215CFM |

| 8 | Exhaust Blower Watt/CFM | 71 watt/215CFM |

| 9 | Electric Heater in Kw | 1 Kw- Room Tempt to 80 Degree Celsius |

| 10 | Compressor Air Required | Filter Air with min 2 Bar Pressure supply should be provided by Client. |

| 11 | Electric Supply | Single Phase 220V 50Hz or Single phase 110V/50 Hz |

| 12 | Electric Points Required | a. For Main machine- 16 Amp. b. Compressor – 16 Amp. c. For Peristaltic Pump – 16 Amp |

| 13 | Spray Gun | SS 316 with 1.00 mm Orifice. (Can Modify Diameter as per requirement) End Connection For Liquid 1/4 BSP (F) For Atomised Air 1/4 BSP |

| 14 | Peristaltic Pump | Head – Single 1.00-4.00 mm bore size with wall thickness of 1.5mm. Display – 3 digit LED display for RPM Duel Roller with spring-loaded Truck. |

| 15 | Pneumatic Control | The customer has to ensure the supply of oil-free compressed air, also free from any other impurity which may contaminate the product. Air Filter and Air water separator are also provided with the machine. Pressure regulator is provided to regulate the desired air pressure. Air Filter and Controlled to control Air of Spray Gun |

| 16 | Different Mounting angle | 45 to 60 degree |

| 17 | Exhaust Arrangement | Yes |

| 18 | Pan Motor | 0.05 HP |

| 19 | VFD Drive | For Speed Controlling from 5 to 100 rpm |

| 20 | MOC | Contact Part SS 316/ Non Contact part SS 304 |

| 21 | Finish | Internal – Mirror External Matt |

| 22 | Electric Consumption | 3.5 Kw@230V, 50 Hz |

| 23 | Dimension (LXWXH) in mm | 600mm X 400 mm X 1200 mm approximately |

| 24 | Weight | 90 kg / 150 kg with packing |

Installation Requirements

Key requirements for the proper functioning of the R&D Coater include:

- Level Base: The coater must be placed on an extremely leveled base to ensure its correct operation.

- Compressed Air: It requires a source of compressed air to power certain components or processes.

- Electricity: Electricity is essential to operate the various electrical components and systems within the coater.

- Effective Earthing: Proper grounding and earthing of the equipment must be ensured to enhance safety and prevent electrical hazards.

Safety Features

- Emergency stop switch.

- Auto stop feature when process time completes.

Certifications

01.

CE Certificate

02.

GMP Certificate

03.

ISO Certificate

04.

MSME Certificate

Frequently Asked Questions

These FAQs provide comprehensive information about the R&D Tablet Coater, covering its purpose, features, materials, operation, and technical specifications.

What is the primary purpose of the R&D Tablet Coater in the pharmaceutical industry?

The R&D Tablet Coater is designed to handle smaller trial batches of tablets and granules for the purpose of coating them with various materials during the research and development phase of pharmaceutical formulation development.

Can you explain the key features of the Pharma R&D Tablet Coating Machine?

Certainly. The key features include a self-contained design, stainless steel (SS 304) exterior, precise pan positioning at 35° to 45°, advanced control panel for customization, and the ability to handle smaller batches effectively.

Why is stainless steel (SS 304) chosen for the exterior of the tablet coater?

SS 304 is selected for its resistance to corrosion and ease of cleaning, making it ideal for pharmaceutical equipment that requires high hygiene standards and durability.

How does the tablet coater ensure uniform coating of tablets and granules?

The coater uses the rotary momentum of the coating pan, which is supported at a tangential angle of 35° to 45°. Interior baffles inside the pan are provided to tilt the contents for efficient and uniform coating.

What is the significance of the spray gun in the tablet coating process?

The spray gun plays a crucial role in the film coating process by delivering finely nebulized droplets of the coating solution onto the moving bed of tablets, ensuring even and consistent coverage.

How are tablets dried during the coating process?

Tablets are dried by directing a stream of hot air onto the tablet bed. The exhaust temperature typically ranges between 60°C and 80°C, which helps enhance the coating process.

What are the prerequisites for effective use of the R&D Coater?

To use the R&D Coater effectively, you need a leveled base, a source of compressed air, access to electricity, and proper grounding (earthing) to ensure the equipment’s safety and functionality.

Could you provide the technical specifications for the R&D Coater?

Certainly, here are the technical specifications:

- Motor Drive: 0.2 kW/0.25 hp Single Phase (1PH)/230V

- Motor: Induction motor 40 watts

- Electrical Services: As per country requirement

- RPM: 3 to 150 rpm

- Foundation: Self

- Blower: 0.50 hp

- Heater: 1.0 kW

- Height: 1215mm

- Width: 400 mm

- Length: 605 mm

- Weight (Approx.): 110 Kg

- Model No.: VJRD-01

International Clients

Industrial Clients

IITs, AIIMS, CSIR, Government and Private Institutes

Related Products

Lab-Scale Rapid Mixer Granulator

VJ Instruments’ Lab-Scale Rapid Mixer Granulator: Perfect for Small-Scale Granulation Trials Welcome to VJ Instruments,

Lab-Scale Fluid Bed Dryer

VJ Instruments’ Lab-Scale Fluid Bed Dryer: Precision Drying for Research and Development Welcome to our

Fluidized Bed Processor

VJ Instruments’ Fluidized Bed Processor: Revolutionizing Research and Development Welcome to the world of innovation

Fluid Bed Top Coater

VJ Instruments’ Revolutionizing Coating and Drying: Introducing the Fluid Bed Top Coater VJ Instruments proudly